Brass Automotive and Aerospace Parts: Key to High-Performance and Reliability

Brass, a durable and versatile alloy of copper and zinc, is a preferred material in the automotive and aerospace industries.

Known for its strength, corrosion resistance, and excellent machinability, brass is used to manufacture a wide range of components that ensure the reliability and efficiency of complex systems.

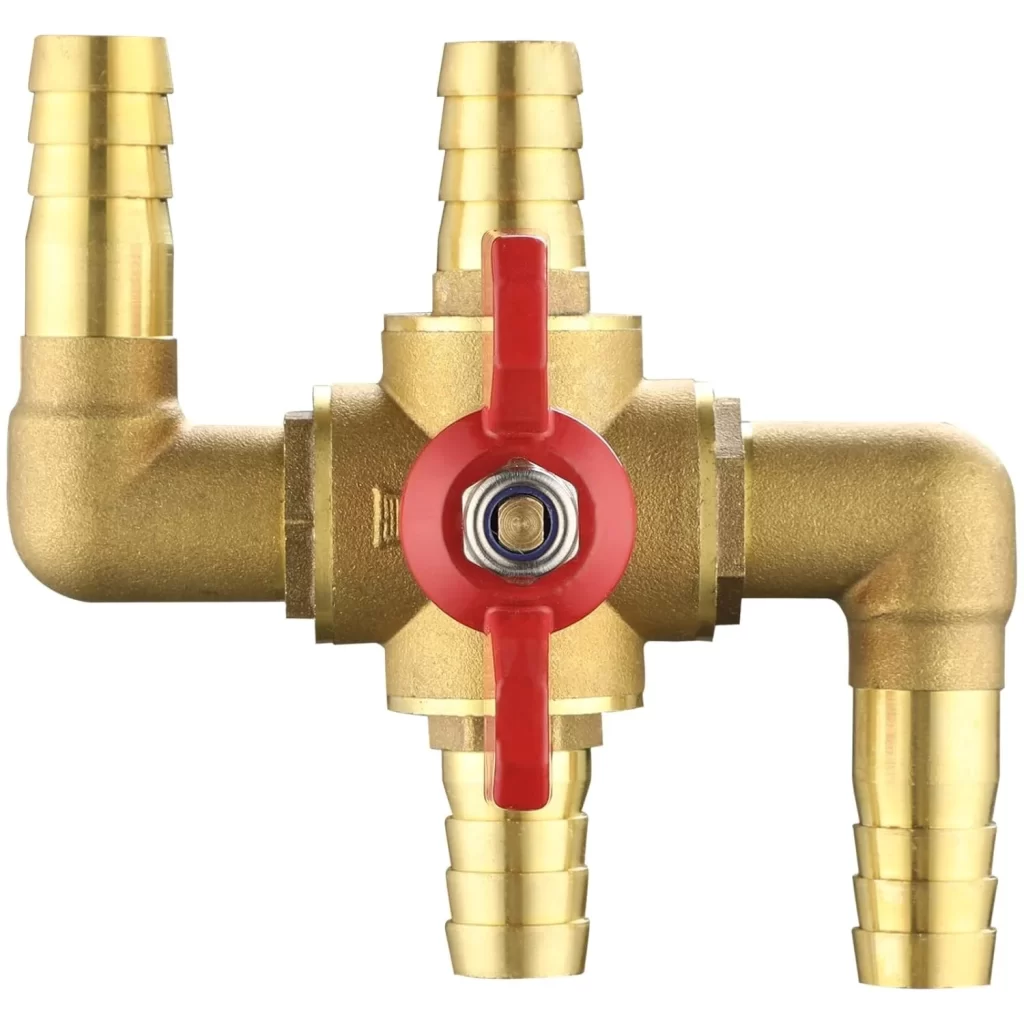

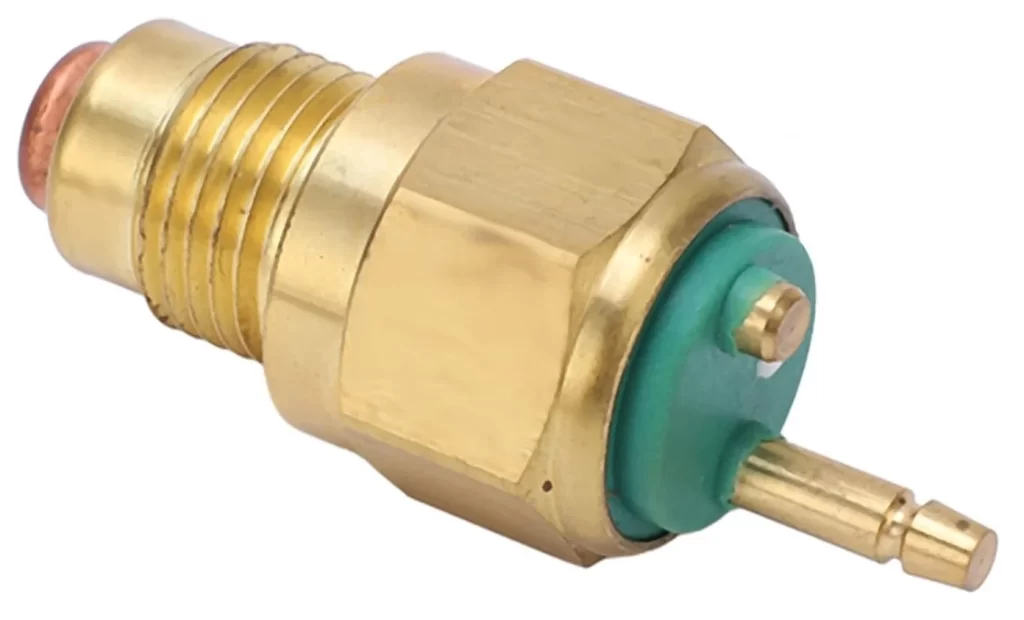

From precision fittings to connectors, brass parts are vital for the performance and safety of vehicles and aircraft.

Why Brass is Ideal for Automotive and Aerospace Parts

The unique properties of brass make it an exceptional material for demanding applications in these industries:

- Corrosion Resistance: Brass components can endure exposure to fuel, water, oil, and harsh environmental conditions without degrading.

- High Strength-to-Weight Ratio: Provides the necessary durability while keeping components lightweight—an essential factor in aerospace applications.

- Thermal and Electrical Conductivity: Brass ensures optimal performance in electrical systems and heat transfer components.

- Precision Machinability: The alloy’s malleability allows for the production of intricate and high-precision parts.

- Non-Magnetic and Non-Sparking: Enhances safety in environments where sparks or magnetic interference could be hazardous.

Applications of Brass in Automotive and Aerospace Industries

Brass parts are used in a wide array of applications, each contributing to the smooth operation of vehicles and aircraft:

1. Automotive Applications

Brass components in the automotive industry ensure durability and efficiency in various systems:

- Fuel Systems: Brass fittings, valves, and connectors are crucial for leak-proof fuel delivery.

- Electrical Systems: Terminals, connectors, and wiring harnesses made from brass provide reliable conductivity.

- Cooling Systems: Radiator fittings and heat exchangers use brass for its thermal conductivity and corrosion resistance.

- Brake Systems: Brass parts ensure precision and reliability in hydraulic braking systems.

2. Aerospace Applications

In the aerospace industry, brass is indispensable for its lightweight strength and resistance to extreme conditions:

- Fluid Transfer Systems: Brass fittings and connectors ensure leak-proof transfer of hydraulic fluids and fuels.

- Electrical Components: Used in terminals, connectors, and grounding systems to ensure stable electrical performance.

- Instrumentation: Brass is often used in components for gauges, sensors, and control systems requiring high precision.

- Structural Components: Select brass parts are used in non-load-bearing structures for added durability and resistance to wear.

Benefits of Using Brass Automotive and Aerospace Parts

- Enhanced Durability: Brass parts withstand wear and tear, ensuring long-term reliability.

- Reduced Maintenance Costs: Corrosion resistance minimizes the need for frequent replacements or repairs.

- Precision Engineering: Brass’s machinability allows for the production of intricate parts with tight tolerances.

- Eco-Friendly: Brass is recyclable, making it a sustainable choice for modern industries.

- Safety Assurance: Non-sparking properties ensure safe operation in volatile environments.

Key Considerations When Selecting Brass Parts

When choosing brass components for automotive or aerospace use, consider the following factors:

- Material Grade: Different grades of brass are suited for specific applications based on their composition.

- Standards Compliance: Ensure components meet industry standards such as ISO, ASME, or SAE specifications.

- Design and Compatibility: Components must be designed to integrate seamlessly into the overall system.

- Plating and Coating: Options like nickel or chrome plating enhance durability and resistance to wear.

Conclusion

Brass automotive and aerospace parts are indispensable for ensuring the performance, safety, and reliability of vehicles and aircraft.

Their unique properties, including corrosion resistance, machinability, and durability, make them a preferred choice for critical systems.

By investing in high-quality brass components tailored to specific requirements, manufacturers can achieve superior efficiency, reduce maintenance costs, and enhance the sustainability of their operations.

Whether in high-speed automobiles or cutting-edge aircraft, brass parts are key contributors to the future of transportation.