Brass Fitting Parts: Versatile Components for Diverse Industrial Applications

Brass fitting parts play a pivotal role across industries due to their durability, versatility, and corrosion-resistant properties.

These components are crafted using brass, a highly malleable and reliable alloy made of copper and zinc.

From plumbing to automotive industries, brass fittings are indispensable for creating secure and efficient connections.

Why Brass is Ideal for Fitting Parts

Brass is a preferred material for manufacturing fitting parts due to several inherent qualities:

- Corrosion Resistance: Brass can withstand exposure to water and other liquids, making it ideal for plumbing and hydraulic applications.

- High Malleability: This property allows for intricate designs and precise manufacturing.

- Thermal and Electrical Conductivity: Brass fittings are excellent conductors, making them suitable for electrical applications.

- Durability: Brass components are strong and have a long lifespan, ensuring reliability in critical applications.

- Aesthetic Appeal: The golden hue of brass provides a polished, professional look in various applications.

Common Types of Brass Fitting Parts

Brass fitting parts come in numerous shapes and sizes to suit specific needs:

Compression Fittings

- Used in plumbing and gas systems.

- Provide a leak-proof seal between pipes or tubing.

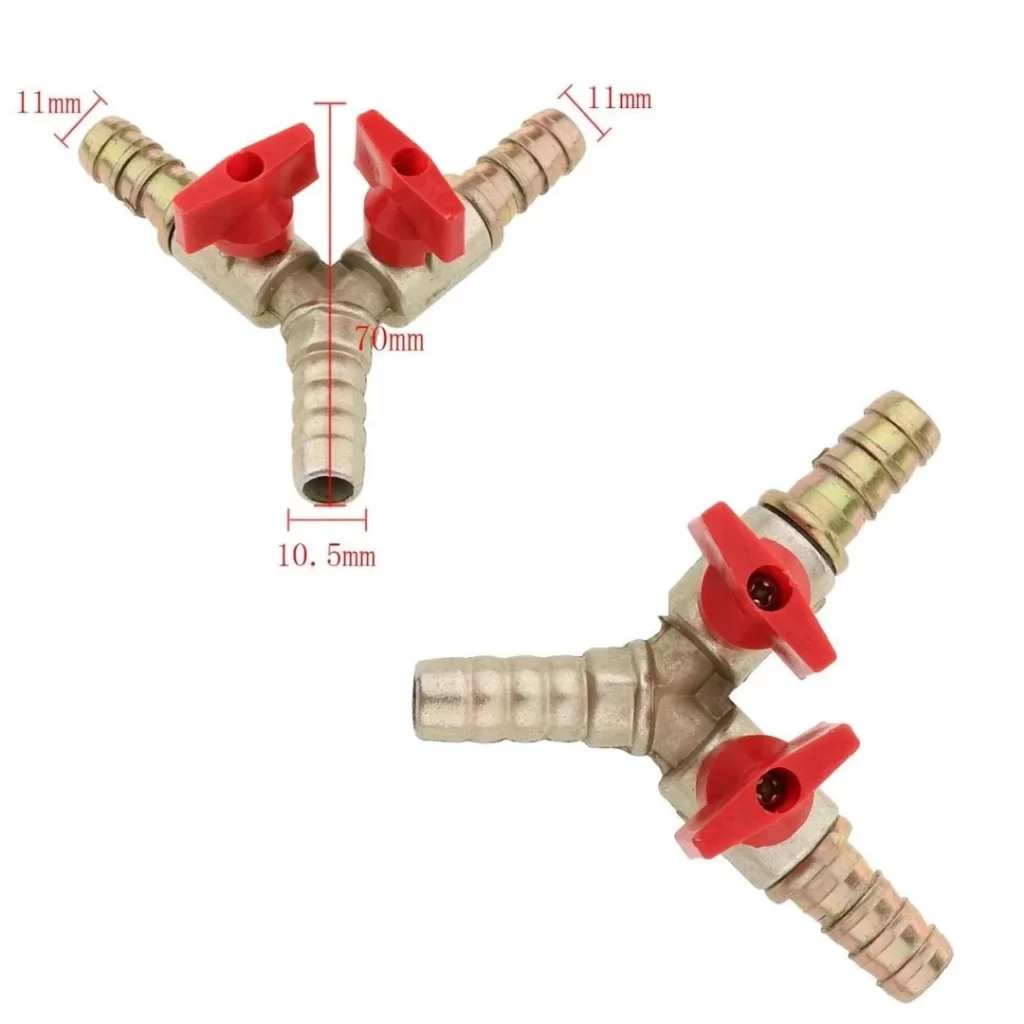

Elbows and Tees

- Change the direction of flow or split it into multiple directions.

- Commonly used in HVAC systems and water pipelines.

Adapters and Couplings

- Facilitate connections between different types of pipes or tubing.

- Ensure flexibility in complex piping systems.

Flare Fittings

- Commonly used in high-pressure systems.

- Offer a secure and robust connection without the need for soldering.

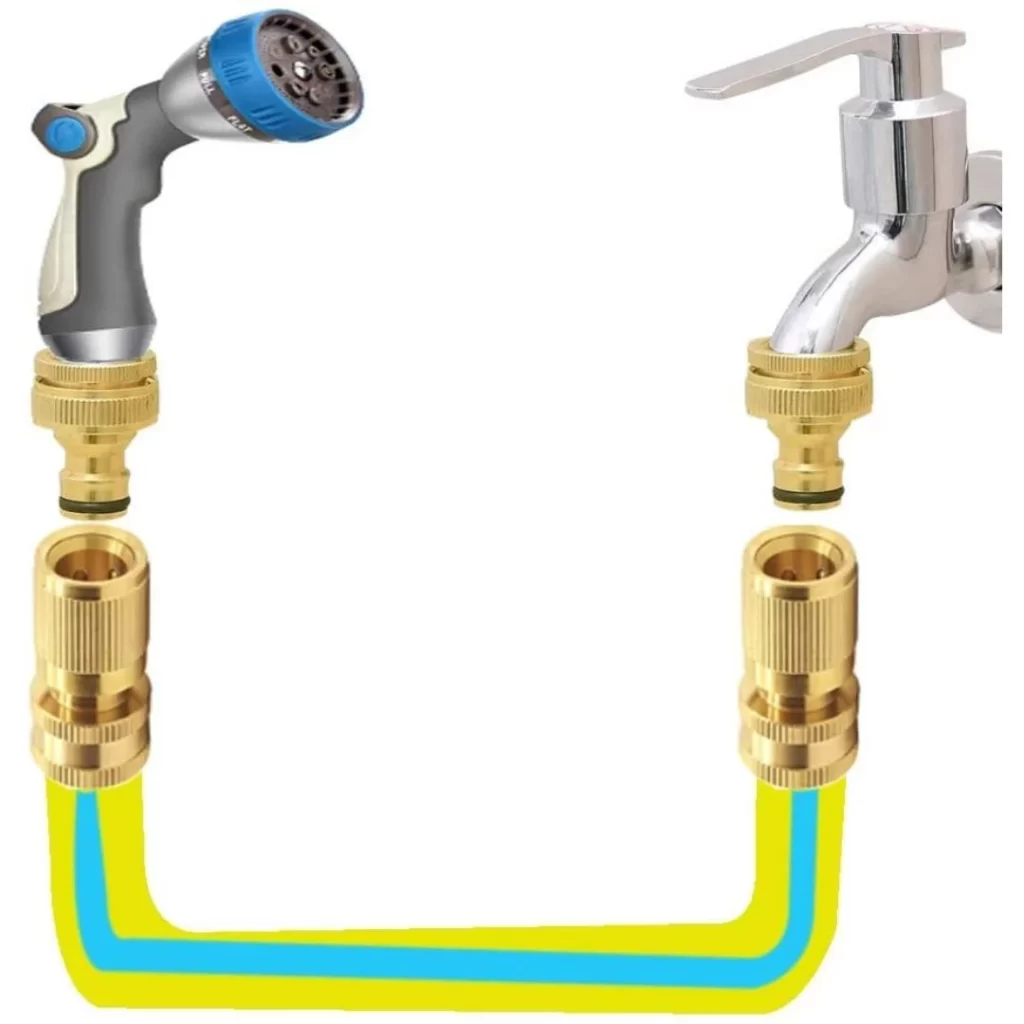

Quick Connectors

- Enable rapid assembly and disassembly of components.

- Widely used in automotive and pneumatic systems.

Industries That Rely on Brass Fittings

Brass fitting parts are utilized in a variety of industries:

- Plumbing and Sanitation: Brass fittings are widely used for pipes, valves, and faucets due to their resistance to water corrosion.

- Automotive Industry: Ensure seamless fluid transfer and secure connections in fuel, brake, and cooling systems.

- HVAC Systems: Essential for air, water, and refrigerant flow control.

- Electrical Industry: Used in connectors, terminals, and switchgear due to excellent conductivity.

- Marine Industry: Resist corrosion in saline environments, making them ideal for boats and ships.

Benefits of Using Brass Fitting Parts

- Versatility: Can be customized for various applications and environments.

- Cost-Effective: Though slightly more expensive than plastic, brass offers unmatched longevity, reducing replacement costs.

- Sustainability: Brass is recyclable, contributing to environmental conservation.

- Ease of Installation: Threaded designs and malleability make brass fittings easy to install and modify.

Key Considerations When Choosing Brass Fitting Parts

To ensure optimal performance, consider the following factors:

- Application Requirements: Assess pressure, temperature, and chemical exposure.

- Size and Compatibility: Select fittings that match the dimensions and material of your piping system.

- Quality Standards: Choose fittings manufactured in compliance with industry standards.

Conclusion

Brass fitting parts are indispensable in modern industrial and domestic applications.

Their unique combination of strength, corrosion resistance, and versatility makes them a superior choice over other materials.

By understanding their types, benefits, and applications, you can make informed decisions for your projects and ensure efficient, durable connections.

Investing in high-quality brass fittings not only enhances system performance but also provides long-term cost efficiency, making them a reliable solution for diverse industries.